OEM Factory for Shampoo Mixing Tank - Mix Tank – JINGYE

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

OEM Factory for Shampoo Mixing Tank - Mix Tank – JINGYE Detail:

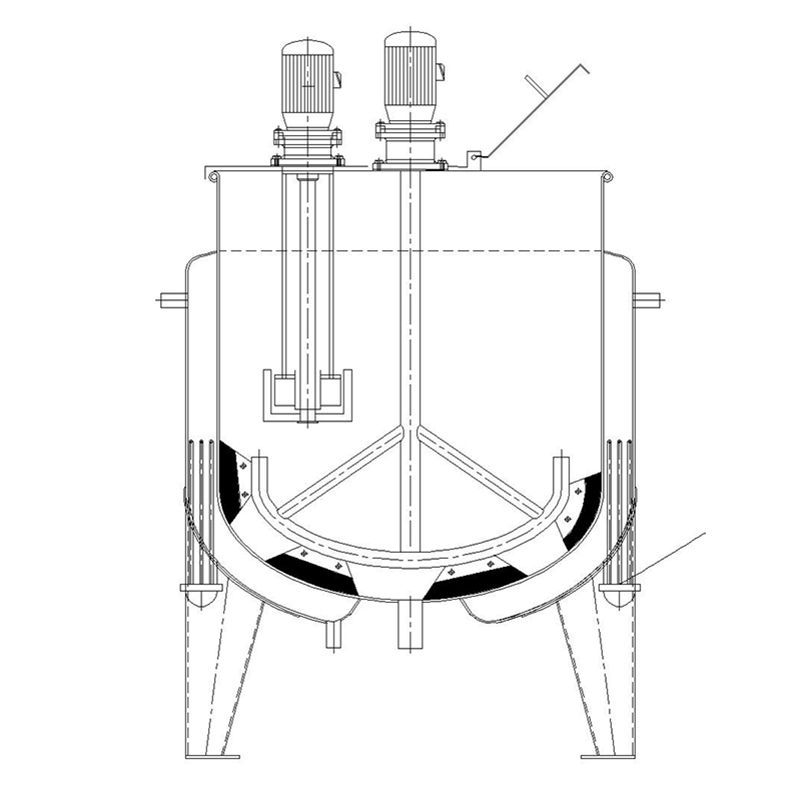

Our mixing tank serves a variety of industries and we have accumulated rich experience in manufacturing&design. Whether you need to add a cover for vacuum or pressure process, add a jacket for cooling or heating, add a mixer for emulsify or disperse, our tank can be designed to ensure your processing process goes smoothly.

JINGYE Mixing Tank is made of stainless steel, capacities range from 100-5000Liters(25-1300Gallons), widely used in:

Food&Beverage Industry:

jam, sauce, ketchup, chilli sauce, hot sauce, pepper sauce, dressing, filling, condiments, salsa, flavorings, puree;

gravy, stew, soup, curry, broth, stock;

tea drink, cider, juice, soy milk, cola;

Pharmaceutical Industry:

Injectable medicine, medicinal ointments & creams, eye drops, Oral syrup;

Personal Care&Cosmetics Industry:

lipstick, shower gel, toothpaste, laundry liquid, detergent, hand sanitizer, shower gel, toilet cleaner, sharing cream, shampoo, hair cream, cosmetics cream mixture, conditioner, body wash, sunscreen lotion, deodorant, skin ointment;

1.Model: JYG series;

2.Volume: 100-5000Liters(25-1300Gallons);

3.Material: all made of SUS304/316L; include the support frame;

4.Voltage: 220/240/380/415V, customized;

5.Heating type: electric, steam;

6.Sanitary flange&valve;

7.Customization requirements are acceptable;

1.Adopt food grade material and sanitary accessories, do not rust, ensure production safety.

2.It can be connected through pipes and valves, with automatic PLC control box, to realize the full automation of the production process, save labor costs, improve production capacity, and profit for customers.

|

Working Volume (L) |

Diameter Φ (mm) |

Deepness D (mm) |

Inner/Jacket (mm) |

Motor Power (kw) |

Mixing Speed (rpm) |

|

100 |

500 |

500 |

2 |

0.37 |

0-63 |

|

200 |

600 |

700 |

2 |

0.55 |

0-63 |

|

400 |

800 |

800 |

2 |

1.1-3 |

0-63 |

|

500 |

800 |

900 |

2 |

1.5-5 |

0-63 |

|

600 |

900 |

900 |

2 |

1.5-5 |

0-63 |

|

800 |

1000 |

1000 |

2 |

1.5-5 |

0-63 |

|

1000 |

1000 |

1200 |

3 |

3-7.5 |

0-63 |

|

2000 |

1200 |

1500 |

3 |

2.2-11 |

0-63 |

|

3000 |

1600 |

1500 |

4 |

5.5-11 |

0-63 |

|

5000 |

1800 |

2400 |

6 |

11-15 |

0-63 |

|

We can customize the equipment according to customer requirements. |

|||||

1.Heating Type

We offer three types of heating, customers can choose the appropriate heating method according to their own conditions of use;

– liquid propane/natural gas heating type;

– electric heating;

– steam heating;

2.Auto tilting type

This machine can adopt auto tilting, turning over the pot to discharge materials, without disassembly and installation of agitator, saving manpower, reducing labor intensity, is a food processing equipment with excellent performance.

If you don’t see a suitable machine that meets your needs, or are overwhelmed by the choices, just call us. We will put our decades of experience and expertise to work for you.

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for OEM Factory for Shampoo Mixing Tank - Mix Tank – JINGYE, The product will supply to all over the world, such as: Canada, Portugal, Greece, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.