Manufacturer for Pasturized Milk Production Line – Turn-Key Tomato Paste Line – JINGYE

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Manufacturer for Pasturized Milk Production Line – Turn-Key Tomato Paste Line – JINGYE Detail:

raw material selection → cleaning → dressing → hot scalding → beating → heating concentration → canning → sealing → sterilization → cooling → finished product.

Operation hints of ketchup production line:

1.Raw material selection: choose fully mature, bright color, high dry matter content, thin skin, thick flesh, less seeds of the fruit as raw material.

2.Cleaning: wash the sand and dirt on the fruit surface with clean water.

3.Trim: remove the stems and green and rotten parts.

4.Hot scalding: Pour the trimmed tomatoes into boiling water for 2 ~ 3 minutes to soften the pulp and make it easier to beat.

5.Pulping: after scalding, pour the tomatoes into the pulper, break up the pulp and remove the skins and seeds.The first mesh diameter is 1.0 ~ 1.2 mm, the second mesh diameter is 0.8 ~ 0.9 mm. Immediately after beating, the pulp is heated and concentrated to prevent pectinase from delamination.

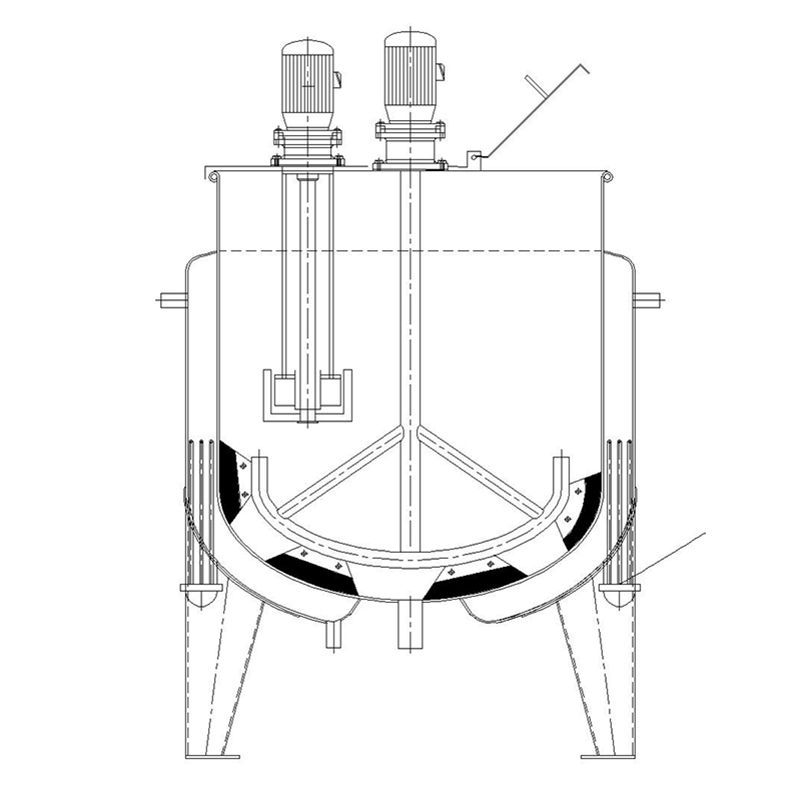

6.Concentration: put the slurry into a planetary stirring interlayer, heat and concentrate, and stop heating when the soluble solid reaches 22% ~ 24%.Keep stirring during the concentration process to avoid burning.

7.Packing: after concentration, slurry temperature is 90 ~ 95℃, immediately can and seal.

8.Sterilization and cooling: sterilization in boiling water at 1O ℃ for 20 ~ 30 minutes, and then cooling until the tank temperature reaches 35 ~ 40℃.

Ketchup production line quality requirements: sauce body is reddish brown, uniform, with a certain viscosity;Sour taste, no peculiar smell;The soluble solids reached 22% ~ 24%.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Manufacturer for Pasturized Milk Production Line – Turn-Key Tomato Paste Line – JINGYE, The product will supply to all over the world, such as: Saudi Arabia, Peru, Algeria, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.