Emulsify Mixing Tank

Short Description:

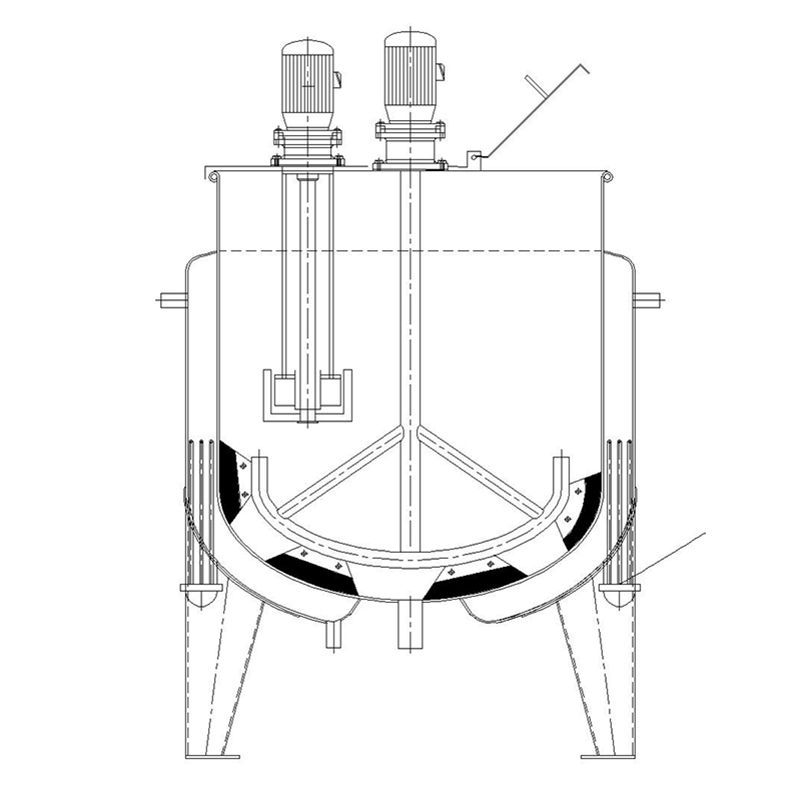

JINGYE High Shear Mixing Tank, also called emulsify mixing tank, the special emulsifying/high shear mixer gave him special functions in mixing.

Product Detail

Product Tags

It has the ability to blend powder and liquid perfectly, shearing powder particles to micron diameter and creating a smooth final product that completely solves the problem of layering.They also help reduce the size of oil droplets in the mixture of water and oil.

JINGYE Emulsify/High Shear Mixing tank is made of stainless steel, capacities range from 100-5000Liters(25-1300Gallons), widely used in:

Food&Beverage Industry:

mayonnaise, tea drink, cider, juice, powder mixture type beverage;

Pharmaceutical Industry:

Injectable medicine, medicinal ointments & creams, eye drops, Oral syrup;

Personal Care&Cosmetics Industry:

lipstick, shower gel, toothpaste, laundry liquid, detergent, hand sanitizer, shower gel, toilet cleaner, sharing cream, shampoo, hair cream, cosmetics cream mixture, conditioner, body wash, sunscreen lotion, deodorant, skin ointment;

1.Volume: 100-2000Liters(25-530Gallons);

2.Material: all made of SUS304/316L; include the support frame;

3.Voltage: 220/240/380/415V, customized;

4.Heating type: electric, steam;

5.Sanitary flange&valve;

6.Customization requirements are acceptable;

1.Adopt food grade material and sanitary accessories, do not rust, ensure production safety.

2.It can be connected through pipes and valves, with automatic PLC control box, to realize the full automation of the production process, save labor costs, improve production capacity, and profit for customers.

|

Working Volume (L) |

Diameter Φ (mm) |

Deepness D (mm) |

Scraper Mixer |

Emulsify Mixer |

||

|

kw |

R/min |

kw |

R/min |

|||

|

100 |

500 |

500 |

0.37 |

0-63 |

0.75 |

0-3200 |

|

200 |

600 |

700 |

0.55 |

0-63 |

1.1 |

0-3200 |

|

400 |

800 |

800 |

1.1-3.0 |

0-63 |

2.2-4.0 |

0-3200 |

|

500 |

800 |

900 |

2.2-4.0 |

0-63 |

2.2-4.0 |

0-3200 |

|

600 |

900 |

900 |

2.2-5.5 |

0-63 |

3.0-5.5 |

0-3200 |

|

800 |

1000 |

1000 |

3.0-5.5 |

0-63 |

5.5-7.5 |

0-3200 |

|

1000 |

1000 |

1200 |

3.0-7.5 |

0-63 |

11-15 |

0-3200 |

|

2000 |

1200 |

1500 |

5.5-7.5 |

0-63 |

15-18.5 |

0-3200 |

|

We can customize the equipment according to customer requirements. |

||||||

1.Heating Type

We offer three types of heating, customers can choose the appropriate heating method according to their own conditions of use;

- no heating type;

- electric heating;

- steam heating;

2.Mixer Type

We offer two types of mixer, each with its own advantage for various processing applications.

- single motion scraper mixer

- double motion mixer

If you don’t see a suitable machine that meets your needs, or are overwhelmed by the choices, just call us. We will put our decades of experience and expertise to work for you.